The flow of work

In a page here, We introduce the flow of the work of the Katayama Manufacturing.

The whole of work of Katayama Manufacturing

<Putting everything into the manufacture of dies that will delight out customers>

The metal mold-making of the Katayama Manufacturing is made from ten process.

- Receiving of Order

- Process Plan, Die Dessign

- Forming Simulation & Modeling

- CAM DATA

- Machining

- Assembling

- Tryout

- Modification after Tryout

- Fine-Tuning

- Delivery and After Service

1:Receiving of Order 2:Process Plan, Die Dessign

<Convert customer need and want to concrete idea and shape.>

Our business begins from listening to customer needs and wants.

Our experienced engineers grasp directly to the customer's requirement before to process plan and die design.

3:Forming Simulation & Modeling 4:CAM DATA

<The best die design and forming simulation by CAD system.>

We adopt new CAD/CAM system.

The dies are designed and manufactured by effective CAD/CAM system.

It links to high Quality, short Lead Time and better Cost preformance.

We can match 3D design and manufacturing if customers require.

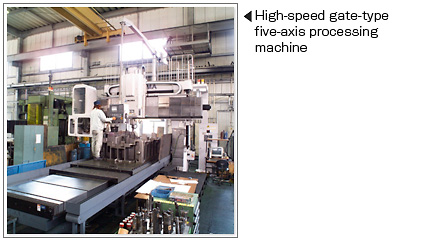

5:Machining 6:Assembling

<Assure high Quality and Short Lead Time by "Parallel Production System".>

The feature of our die manufacturing is "Parallel Production System" using high accurate NC machines.

Not only large parts but also small parts of dies are machined by NC machining center in our system, so can manufacture and deliver easily changeable parts if required in maintenance stage.

We adopt NC Machining as possible in order to eliminate the difference by manual working.

Namely we change from "Finishing" to "Assembling" as likes automobile production.

By changing from "Series Production System (old Style)" to "Parallel Production System (new style)", we could achieve high accuracy and short lead time.

And then it enables to revise easily in maintenance stage by "Parallel Production System".

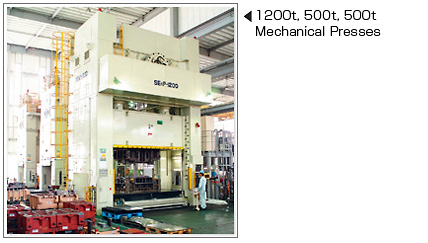

7:Tryout

<High accurate and well maintained 1200 ton Trial Press assures Quality of Dies.>

Our factory is equipped with one 1200 ton trial press, two 500 ton.

To thoroughly implement all trial on large parts in house, this allows us to maintain high levels of reliability and quality.

And this also allows us to prevent any unexpected trouble occurring when the dies are used on customer production line.

Adjustment of "Fingers" in transfer press are done by Transfer simulator in our Plant, so it can mostly reduce final tuning time in customer transfer press (2 hours per part).

8:Modification after Tryout

<Accurate indication by experienced engineers in Tryout and Back up on modificated data.>

In case of troubles occurring in tryout, our experienced engineers implement accurate modification.

Modificated data will be fed back to machining and then re-tryout.

This process will be repeated unitil the quality level is attained.

The latest modificated data are backed up for each part.

It ensures that the same part can be exactly provided if needed in maintenance stage.

One of the main features of Katayama Manufacturing Co.,Ltd. is the fact that we are able to perform die maintenance both easily and smoothly.

9:Fine-Tuning 10:Delivery and After Service

<Manufacturing and Delivery of Dies that provide full Satisfaction.>

Guaranteeing high level of quality and keeping delivery date strictly are the top priority in Katayama Manufacturing Co.,Ltd.

To be constantly and continuously selected, we provide products that gets the full satisfaction of our customers.